Elon Musk and Space X's Product Design Engineering (PDE) on High Technology Spacesuits

Product Design Engineering (PDE) encompasses wide array of its application. With this spirit, Product Design Engineering (PDE) Program in BINUS ASO School of Engineering (BASE) provide insights for its students on current cutting edge technology, within the scope of PDE.

This article conveys the High Technology Spacesuits, in particular for SpaceX's purpose, in addition to benchmark from NASA. This article is adapted and originated from

https://oig.nasa.gov/docs/IG-21-025.pdf on NASA's Report on Development of Next-Generation Spacesuits and https://design-milk.com/the-design-of-the-spacex-spacesuit-explained/ and Operational Requirement of Spacesuit https://www.americanscientist.org/article/the-past-and-future-space-suit and https://www.youtube.com/watch?v=rD2IgeIkK8U

The Design of the SpaceX Spacesuit Explained

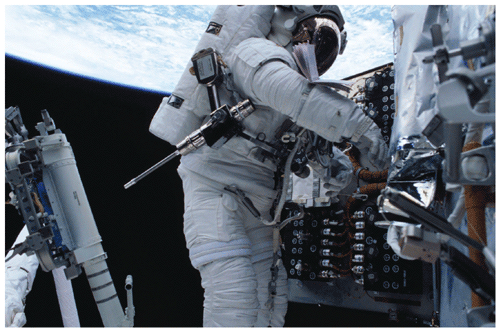

For a glorious moment we were given a glimpse of the future of space travel. The successful launch of SpaceX’s Falcon 9 reorbital rocket system carrying the Crew Dragon to the International Space Station was historic in successfully sending NASA astronauts Bob Behnken and Doug Hurley within a privately developed spacecraft. The mission also revealed the next generation of astronautical wear, the SpaceX spacesuit.

“Obviously it’s protecting the crew’s head…but it also houses the microphones, as well as the valves that are regulating pressure in the suit. We had to design the gloves so that they would work with the touchscreen, so the gloves also have to do a number of other things like the rest of the suit. So all of those things had to come together…the suit is not just a piece of hardware, it’s not just a suit. It’s a very personal thing. It’s Bob’s suit. It’s Doug’s suit.”

Operational Requirement of High Technology Spacesuits

https://www.americanscientist.org/article/the-past-and-future-space-suit indicates that

The creation of an effective space suit begins with a fundamental understanding of the environments in which the suit will be used and the capabilities the suit will need. This information is used to develop a set of requirements that guide engineers and technicians in the selection of materials, design of components, test protocols, and overall configuration of the space suit system.

Space suits are typically thought of as being used in environments such as low Earth orbit and the surface of the Moon. However, they are often designed to operate also during numerous mission phases beyond spacewalks, or extravehicular activity (EVA), including launch, abort, landing, and emergency operations, which further increase their complexity. In low Earth orbit, the astronaut must be protected from and operate in the vacuum of space, as well as thermal extremes ranging from +120 degrees Celsius to –150 degrees, microgravity, rapid changes from intense sunlight to absolute darkness as the Earth is orbited every 90 minutes, and micrometeoroids and orbital debris traveling at speeds ranging from 8 to 16 kilometers per second. In other words, it is a very dangerous and difficult place to live and work, so a space suit has to function flawlessly.

The environmental challenges increase on the Moon or planetary bodies. In addition to the same threats encountered in low Earth orbit, the Moon has one-sixth the gravity of Earth, which alters human motion, and it is covered with fine particles of lunar dust that are sharp-edged and abrasive. The dust, if not managed correctly, can quickly degrade materials and clog bearing joints, rendering a suit ineffective. Mars, on the other hand, has three-eighths the gravity of Earth, has a slight atmosphere, and appears to have more forgiving soil that has been worn down by wind so it is not sharp-edged, but in some cases may include chemical oxidants that can degrade polymeric materials.

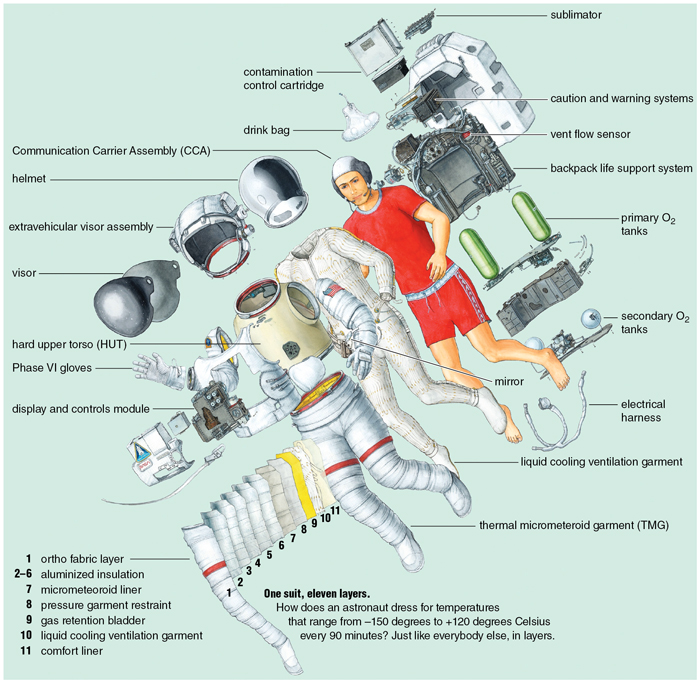

Space Suit Components

Space suits are really single-occupant spacecraft. They consist of an articulated anthropomorphic pressure vessel that conforms to the wearer, known as the space suit assembly, and a portable life support system that typically looks like a backpack. Together, the suit and the life support equipment are called an Extravehicular Mobility Unit (EMU) in NASA terms. Much of the surface area of the space suit is made from softgoods, layers of textiles and flexible membranes (See figure below). They are sewn and thermally bonded together to make an airtight vessel that is pressurized with pure oxygen to 29.7 kilopascals. The result is similar in composition to a football or basketball. The suit consists of three major layers: the bladder that contains the oxygen, the restraint that provides the structure, and the thermal and micrometeoroid layer that provides protection from the environments. Each of these assemblies performs specific functions and operates independently, but they must collectively function as a single unit to help maintain the breathing atmosphere, pressure, and temperature necessary to protect the astronauts from the space environment. Together, a total thickness of less than one-tenth of an inch protects the astronaut from space.

Comments :